Hey guys, thought I'd put together a bit of a detailed look at how decreasing your pulley size will effect power and boost. Keep in mind this will also increase your MAT and overall temps.

I based this off of Merry Frankster evaluating Rotrex chargers over on MR2OC (so stealing a bit of his language).

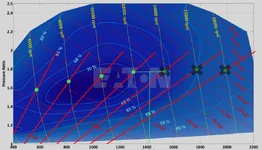

I grabbed the below chart for the Eaton 1740 supercharger. Basically these charts give a description of the operational parameters of each supercharger. At any specific impeller RPM, the compressor is capable of producing a range of flowrate and pressure. This range is represented on the chart as the isocline for that RPM: 6k, 8k, 10k, 12k, 14k, 16k, 18k, and the service limit is rated at 20k RPM.

Do dive deeper we need to know the relation between these points and the engine's RPM

RPM (engine) = RPM (impeller) / ( P.D. (crank diameter) / S.C. (pulley diameter) )

The 2GR has a 142mm drive pulley (5.59055"). Since we're looking at SC pulley's in inches.

This brings us to the below numbers. Keep in mind everything above 7,200 engine RPM you NEED internal upgrades. Valve springs up to 7,600ish and rods above that. Another words, stock pulley is never going to reach 16,000 SC RPM, but it is possible with a 2.5" pulley on stock internals (temperature limiting, do so at your own risk).

The next step is to answer the question: How much air does the engine draw at any given RPM and boost level?

EDIT: Quick note, this is post is all calculated at sea level air pressures. Higher altitudes areas like Denver have thinner air and can safely go to smaller pulleys than running the same at sea level.

The mass of air drawn by a cylinder on its downstroke is:

Mass (air) = Density (air) x V(cylinder) x (Pressure ratio) x (Volumetric Efficiency)

Therefore the air drawn by the engine over time is 1/2 times this - (when talking about a four-stroke engine) - times the RPM.

Mass Flow Rate (air) = Air Density x Displacement x PR x VE X RPM / 2.

VE has been logged for estimates (seen below) but I'm using a 90% static number to simplify things.

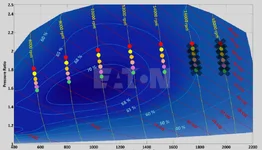

From here we can map pressure ratio vs air flow for given RPMs. We overlay these for each RPM range to the supercharger efficiency chart.

We're looking for where each of these overlaps its correlated isocline. Given data above, we know that the stock 3.0" pulley takes an engine speed of 7,513 RPm to hit the 14,000 isocline. So 7,000 engine RPM comes in near the 13,000 SC RPM point. From here we follow it down to the mass air flow.

This roughly correlates to 1425 KG/hr of airflow. Convert to Lbs/Min and we get 52.36. As a general rule you can multiply this by 9.5-10.5x for maximum horsepower achievable. So lets use 10x.

This means the stock SC configuration generates enough airflow (hypothetically) for up to 524bhp. The dotted red cross lines indicate the SC's draw on the drivetrain. Our intersection is at the 32 kW draw line, which is roughly 42hp. Brining our hypothetical hp down to 482BHP (506BHP capacity if using 10.5x the Lbs/min airflow) Again these are general rules and not set in stone numbers.

Now, for the important part, how does changing pulley size effect max airflow, and resulting HP change. I repeated the process above for pulley size 3.0" (green) to 2.5" (Red) with 0.1" increments for the other colors. X over limits that are unsafe for stock internals.

From here we look at (roughly) where the airflow falls for each pulley size at 7,000 rpm.

So lets look at hypothetically dropping from a 3.0" (green) to a 2.7" (orange).

Mass Flow Rate (KG/hr) moves from 1425 to 1575ish, a 150 kh/hr increase (5.5116 lb/min) Using our HP 10x rule estimation, this is a 55hp gain.

The supercharger parasitic draw increases from 32kW to 44kW. (16hp draw)

Meaning our net increase in airflow minus parasitic draw is ~39 HP gained from the pulley change alone.

Now if you build the engine (or want to risk ruining yours) and shift max RPM up to 8,000 we can see this drastically increases flow, essentially shifting things to the right. The SC becomes less efficient and as can be seen by the kW isoclines (parasitic draw), so you do see diminishing returns between both RPM and increased boost, along with the fact you need to account for temperature and all your engine internals.

Hopefully JB4 / VF / Komotech, etc can work with smaller pulleys and we can see some moderate steps up in performance for some of you guys!

Thanks for attending my Ted Talk.

I based this off of Merry Frankster evaluating Rotrex chargers over on MR2OC (so stealing a bit of his language).

I grabbed the below chart for the Eaton 1740 supercharger. Basically these charts give a description of the operational parameters of each supercharger. At any specific impeller RPM, the compressor is capable of producing a range of flowrate and pressure. This range is represented on the chart as the isocline for that RPM: 6k, 8k, 10k, 12k, 14k, 16k, 18k, and the service limit is rated at 20k RPM.

Do dive deeper we need to know the relation between these points and the engine's RPM

RPM (engine) = RPM (impeller) / ( P.D. (crank diameter) / S.C. (pulley diameter) )

The 2GR has a 142mm drive pulley (5.59055"). Since we're looking at SC pulley's in inches.

This brings us to the below numbers. Keep in mind everything above 7,200 engine RPM you NEED internal upgrades. Valve springs up to 7,600ish and rods above that. Another words, stock pulley is never going to reach 16,000 SC RPM, but it is possible with a 2.5" pulley on stock internals (temperature limiting, do so at your own risk).

The next step is to answer the question: How much air does the engine draw at any given RPM and boost level?

EDIT: Quick note, this is post is all calculated at sea level air pressures. Higher altitudes areas like Denver have thinner air and can safely go to smaller pulleys than running the same at sea level.

The mass of air drawn by a cylinder on its downstroke is:

Mass (air) = Density (air) x V(cylinder) x (Pressure ratio) x (Volumetric Efficiency)

Therefore the air drawn by the engine over time is 1/2 times this - (when talking about a four-stroke engine) - times the RPM.

Mass Flow Rate (air) = Air Density x Displacement x PR x VE X RPM / 2.

VE has been logged for estimates (seen below) but I'm using a 90% static number to simplify things.

From here we can map pressure ratio vs air flow for given RPMs. We overlay these for each RPM range to the supercharger efficiency chart.

We're looking for where each of these overlaps its correlated isocline. Given data above, we know that the stock 3.0" pulley takes an engine speed of 7,513 RPm to hit the 14,000 isocline. So 7,000 engine RPM comes in near the 13,000 SC RPM point. From here we follow it down to the mass air flow.

This roughly correlates to 1425 KG/hr of airflow. Convert to Lbs/Min and we get 52.36. As a general rule you can multiply this by 9.5-10.5x for maximum horsepower achievable. So lets use 10x.

This means the stock SC configuration generates enough airflow (hypothetically) for up to 524bhp. The dotted red cross lines indicate the SC's draw on the drivetrain. Our intersection is at the 32 kW draw line, which is roughly 42hp. Brining our hypothetical hp down to 482BHP (506BHP capacity if using 10.5x the Lbs/min airflow) Again these are general rules and not set in stone numbers.

Now, for the important part, how does changing pulley size effect max airflow, and resulting HP change. I repeated the process above for pulley size 3.0" (green) to 2.5" (Red) with 0.1" increments for the other colors. X over limits that are unsafe for stock internals.

From here we look at (roughly) where the airflow falls for each pulley size at 7,000 rpm.

So lets look at hypothetically dropping from a 3.0" (green) to a 2.7" (orange).

Mass Flow Rate (KG/hr) moves from 1425 to 1575ish, a 150 kh/hr increase (5.5116 lb/min) Using our HP 10x rule estimation, this is a 55hp gain.

The supercharger parasitic draw increases from 32kW to 44kW. (16hp draw)

Meaning our net increase in airflow minus parasitic draw is ~39 HP gained from the pulley change alone.

Now if you build the engine (or want to risk ruining yours) and shift max RPM up to 8,000 we can see this drastically increases flow, essentially shifting things to the right. The SC becomes less efficient and as can be seen by the kW isoclines (parasitic draw), so you do see diminishing returns between both RPM and increased boost, along with the fact you need to account for temperature and all your engine internals.

Hopefully JB4 / VF / Komotech, etc can work with smaller pulleys and we can see some moderate steps up in performance for some of you guys!

Thanks for attending my Ted Talk.

Attachments

Last edited: